Machine Design & Tribology

The lightweight, high efficiency and enviromental load-reducing in machine systems are requiored in oder to achieve the low corbon society. In this laboratpry, Machine Design & Tribology Laboratory, Using the leading-edge surface modification and application of analysis, engineering developments, which improve the functinal capability, performance, fatigue life and transmission efficiency of the machine elements transferring the high torque, are conducted. The research and development on the usage of the machine elements in the extreme enviromental conditions such as space enviroment are conducted with exparimantal and analitical methods.

Masahiro FUJII

Professor

Tribology of SurfaceModified Machine Element

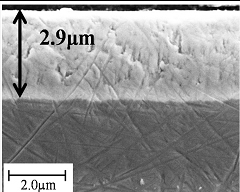

The efficiency and durability of machines are improved by high functional carbon films and high hardness sprayed coatings having μm order in thickness. The technological applications are researched and developed from the point of view of tribology.

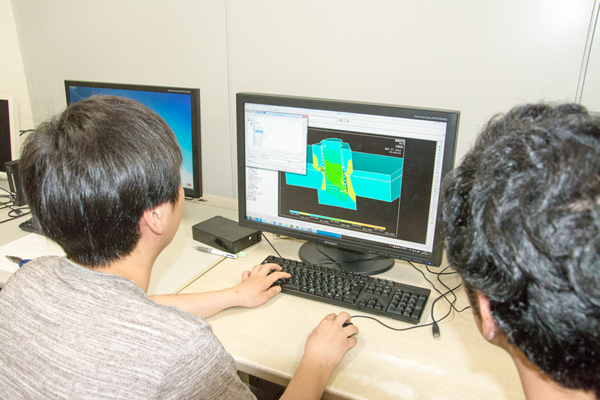

Improvemnent of Surface DUrability of Machine Elements

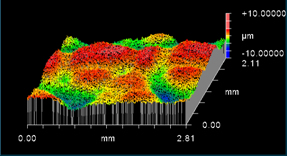

The surface strength is increased with controlling appropriately surface micro-micro profiles, surface hardness, residual stress, and so on. The innovative surfaces having high surface strength as well as good lubricity are developed.

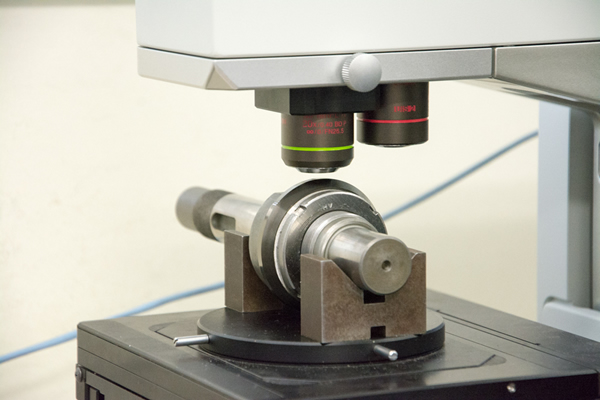

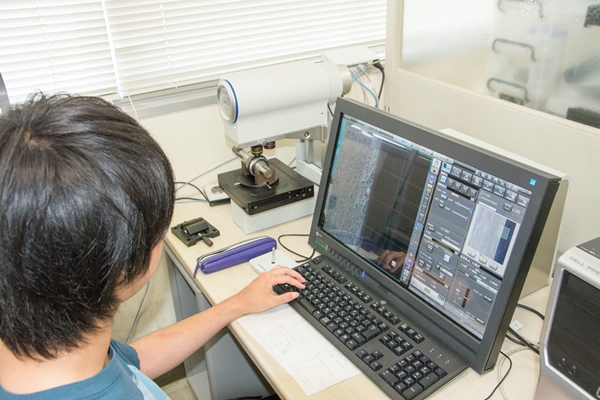

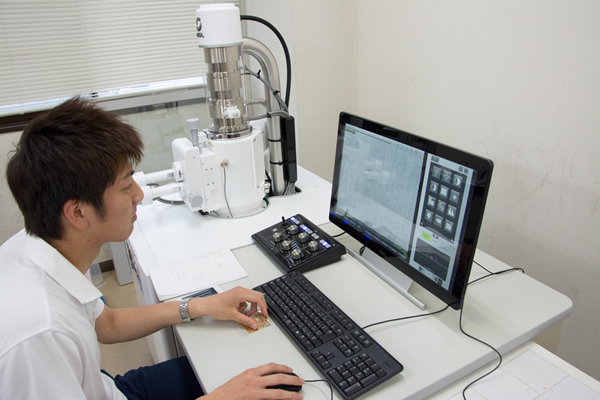

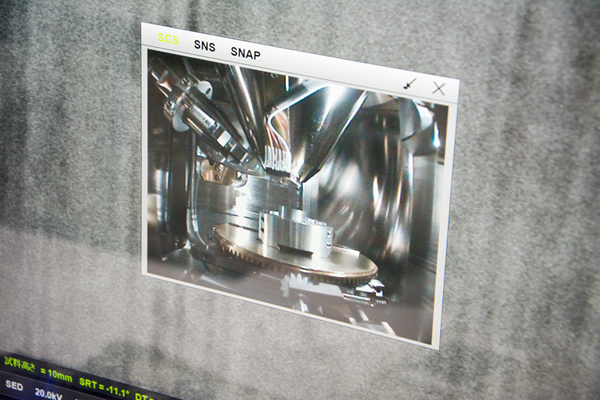

Fig.1 Observation of High Functional Film

Fig.2 Surface Topography Modified with Laser

Tadashi SHIOTA

Associate Professor

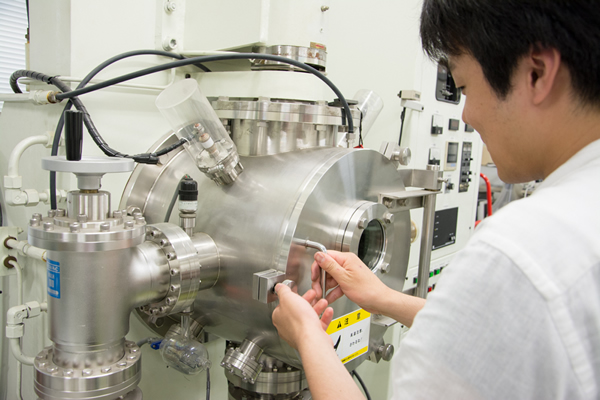

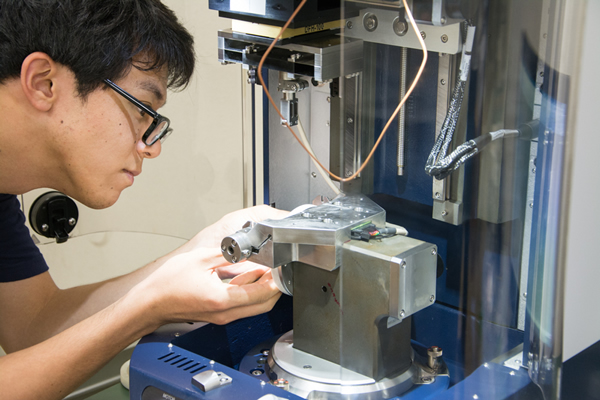

Tribology of Ceramic Composite Coating

Tribological properties are often improved by ceramic hard coating. In advanced mechanical systems such as semiconductor manufacturing systems and medical devices, superlubricity and/or zero wear are required. Tribology of ceramic composite coating are studied to achieve superlubricity and/or zero wear.

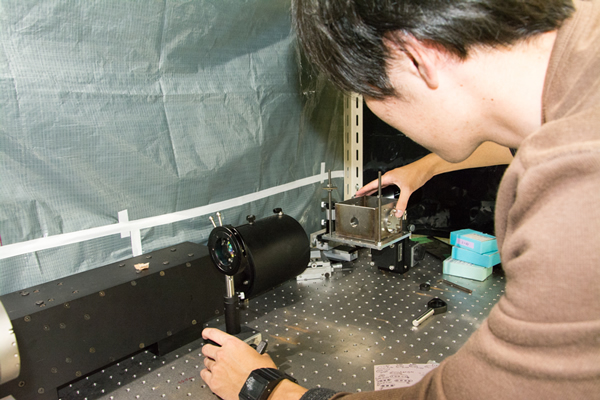

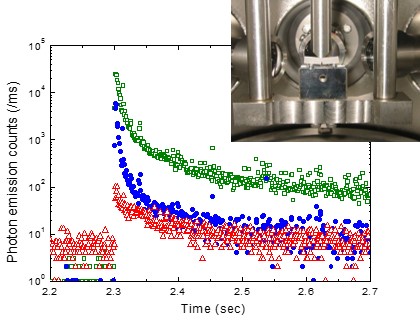

Fundamentals and Applications of Triboemission and Fractoemission

Photons, electrons and ions are often emitted from a material by mechanical stimulus such as friction, wear, deformation or fracture, which are named “triboemission” and “fractoemission”. These emission phenomena are studied to clarify their emission mechanisms and for applications to in-situ observation techniques of friction or wear processes.

Fig.1 Ceramic coating by RF sputtering

Fig.2 Fractoemission detection apparatus and its emission property